The Institute for Sustainability Leadership needed a headquarters that reflected its own values so it set about an ambitiously green retrofit of a former telephone exchange, proving along the way that the most sustainable building is probably the one that already exists

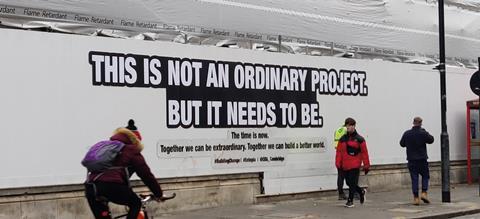

The signs on the site hoardings announce: “This is not an ordinary project. But it needs to be.” That would be a neat summary of what is being delivered behind those same hoardings – a project that hopes to demonstrate to one of the most environmentally polluting industries a way to transition to a sustainable economy and to make retrofitting existing buildings to high standards the norm.

The project itself, which is completely obscured by safety sheeting, is called the Entopia Building: the name is a blend derived from the “En” of Envision, an electric car battery manufacturer which donated £6m towards the cost of the building, and utopia. It will be the new headquarters for the Cambridge Institute for Sustainability Leadership (CISL), part of Cambridge university. As the name suggests, CISL develops leadership solutions for a sustainable economy, so it needed to walk the talk by commissioning a building exemplifying the organisation’s values.

The £12.8m project is a deep green retrofit of a 1930s former telephone exchange in central Cambridge used for offices since the 1990s. The building is being refurbished to the Passivhaus EnerPHit standard, and CISL also want to achieve BREEAM Outstanding and WELL Gold certification too.

An ambitious embodied carbon target of 300kg/CO2/m² has been set over the building’s assumed 100-year life. This includes the carbon embodied in the materials used for the refurbishment, repair and maintenance during the building’s life and deconstruction at the end.

Additionally, CISL has set a target of using 50% bio-based materials for the work. This, coupled with the WELL requirements for good air quality, means sparing use of any petrochemical-based products.

The job was made more challenging as EnerPHit demands a very well-insulated building envelope but the building is in a conservation area which ruled out external wall insulation. The neo-Georgian building also featured traditional, multi-paned box sash windows which the planners wanted to be retained.

According to Wendy Bishop, an associate at architect Architype, one key challenge was trying to get an understanding of what the building was constructed from, to enable a retrofit strategy to be devised that would meet the demanding targets. “We were restricted in terms of some of the opening-up work we could do as the university was keen not to bash holes in things before there was a guaranteed project, so we had to make some assumptions about the building,” she says.

The building is a rectangular block on the corner of Regent Street and Park Terrace and includes a narrower block at the back so that it looks like a T in plan. The section at the back was extended in the 1990s.

The existing building was incredibly gloomy, and we know you need good daylighting for wellbeing

Wendy Bishop, associate, Architype

The original building features a concrete frame and floor slabs with 300mm-thick brick walls. The extension is steel framed, with precast plank floors. According to Bishop, no one understood the extent of the precast planks, which were also used in the toilet areas on each floor. The concrete columns were in worse condition than anticipated, and some steel ones were encased in concrete.

Getting enough natural light into the building was another challenge. “The existing building was incredibly gloomy, and we know you need good daylighting for wellbeing,” explains Bishop.

Modelling revealed that the glazing bars and frame of the Georgian-style windows hogged more than 40% of the window area. Architype proposed replacing the windows with large, tilt-turn ones without any mullions or transoms and recessed behind the window opening so barely any of this was occupied by the frame. This would improve daylighting factors inside the building by between 70% and 80% and offer better thermal performance than windows divided up into smaller panes or fitted within the window opening.

The Cambridge planners took exception to the loss of the Georgian-style windows, so they recommended refusal. Fortunately, the planning committee disagreed with the planning officers and approved the proposal.

“One of the reasons for approval was this was an exemplary project that was addressing the climate emergency,” says Alex Reeve, the sustainable buildings adviser for Cambridge university estate management.

For contractor ISG the pre-construction period where the design is developed into practical, technical solutions was critical. ISG was engaged at RIBA stage 3 under a pre-construction services agreement.

“For me this is a critical piece in these types of projects,” says Chris Chappell, ISG’s contracts director. “A lot of people use the term ‘collaborative’, but a project like this only works if we all work together – and that includes my engineering and design team, the consultants and the client’s team.”

During this period ISG deconstructed the building and “peeled back the layers” to gain a thorough understanding of its construction. This included keeping the raised access floor for reuse and selling the old office furniture to reduce waste.

Having gained a thorough understanding of the building, the team could then devise technical solutions that met the design requirements. Upgrading the building envelope to meet the EnerPHit standard was a particularly critical aspect of the job as this needs to be very airtight and well insulated. The target of 50% bio‑based materials combined with the need to avoid anything that emitted volatile organic compounds ruled out high-performance foamed plastic insulation.

Chappell says that a lot of thought went into developing a simple approach to insulating the internal walls. “We’ve been able to standardise the internal wall treatment to make sure we have a simple palette of materials and a consistent approach for the different interface types and different cross-sections of the wall,” he explains.

“Keeping the detailing as simple as possible with those materials has been really important because, if you make it too complicated, managing the quality becomes more difficult.” Chappell adds that working with a simple palette of materials reduced the risk of supply issues as the impact of Brexit was a real concern during the pre-construction period.

Moving away from modern materials meant using niche suppliers, which presented another risk to ISG. Chappell admits that it was a challenge getting the materials in the quantities needed for this job as they tended to be manufactured in small quantities.

Flexible insulating materials were ruled out too, he adds. “Materials that were loose or came on a roll were discounted because they could slump inside the cavity over time, and we had to guarantee the performance of the external envelope.”

The first step was to spray two 20mm-thick layers of a material called Diathonite to the inside of the brick wall. Made from natural hydraulic lime, diatomaceous earth and cork, this primarily acts as the airtightness layer but also has insulating properties.

The brickwork and insulation build-up are designed to be breathable, which meant there was a risk of moisture from inside the building condensing inside the wall and causing damp. Diathonite helps to regulate moisture in the wall, reducing the risk of damp building up in the wall.

A 40mm layer of Gutex woodfibre insulation board was fixed over the Diathonite with a 120mm thick layer used in the basement. This might not seem much insulation for an EnerPHit project but Bishop says the building has a large floor area relative to the wall area which means smaller heat losses.

“We’ve been very lucky with this building as it has a good form factor which is a great first step to have,” she says, adding that another benefit is offices have relatively high internal gains, which means less insulation is needed.

A freestanding timber stud frame was erected in front of the woodfibre boards with Fermacel boards used to finish the wall. Dulux Evolve, a product that contains 35% recycled paint, has been used to finish the boards.

Thermal bridging has been tackled by insulating the top and bottom of the floor slabs adjacent to the wall. This strip of insulation extends 300-400mm into the building, the layer on top of the slab has been covered over with raised access flooring.

Making the precast concrete plank areas airtight has been done with a product called Blowerproof which is sprayed on the underside of the planks. A product called SonaSpray has been applied to the soffits – this is an acoustic product to improve sound quality in the offices.

Unusually, the windows will be fitted towards the end of the project as the old ones have been left in place. “To deal with WELL we have to be very mindful of air quality testing which has to be carried out before we start, during the process and afterwards,” explains Chappell.

“Park Terrace is a very busy city centre bus route, so what we didn’t want to do was rush to take the windows out.” The windows will be fitted behind the walls – a new structural frame called Winframer was installed to the rear of the wall when the insulation was applied ready for the new windows.

In a big plus for the circular economy, ISG reused 350 LED light fittings that it was stripping out from a London office. These had not been used as the office had been fitted out to Category A standards and was being refitted by the client.

The lights were inspected by the manufacturer, Phillips, and given a new warranty. This approach was cost neutral.

Gwilym Still, partner at MEP engineer Max Fordham, says less engaged clients might not be so enthusiastic about reusing products and getting these recertified: “The challenge is this will be a harder sell on a very commercially focused project where they don’t want to put the effort in and purchase off-the-shelf stuff instead.”

The raised access flooring removed at the beginning of the project was reinstated and second-hand panels purchased to replace ones that were missing or damaged. “It’s the mindset, not to rush out to buy new or rip out what you have got, but consider how you can reuse that material and the best way to do it. We need to change our mindset moving forward as an industry,” Chappell says.

The galvanised steel surface of the floor panels will be cleaned up and left exposed, as carpet tiles have a significant environmental impact. “The floor finishes make or break the embodied carbon target,” Bishop says. She adds that the client was initially concerned about the bare-bones look but was reassured by visiting other projects where this had been done.

So, with the bulk of the project done, what has Chappell learnt from the process? He stresses the criticality of early contractor engagement, ideally at RIBA stage 2 so it can get a good understanding of the building. ISG was engaged at RIBA stage 3, which Chappell suggests was not ideal. “Even at stage 3 you need a good understanding of the building, otherwise you run the risk of discovering too many unknowns and having to change the design – which costs time and money and is something we want to avoid,” he says.

Chappell is also keen to drive the uptake of the bio-based materials that have been used on this project. “We want to promote the wider use of those materials as this will improve availability and drive the economies of scale which will drive better-value building retrofit.”

Another positive is that some of the specialist contractors have been trained up on the installation of these materials – skills which they can take on to other jobs. Only then can this extraordinary project become ordinary.

Souce : Building